- info@microfire.in

- +(91) 99110 01612 | 99244 23947

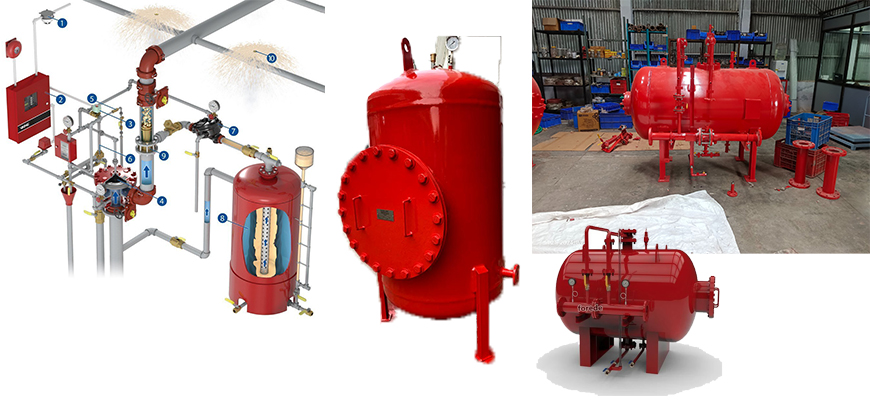

Foam Base System

Low Expansion Water Foam Sprinkler System

Low-expansion foam systems provide vapour suppression with foam blankets that are applied directly to flammable liquids. To be e_ective, coverage needs to be complete. The quantity of foam needed is calculated according to the total surface area of the area to be protected. Also the monitor can used to supply low expansion foam when a large volume of foam is required.

Low-Expansion Blander Tank and Atmospheric Tank

A Low Expansion Blender Tank is a specialized mixing vessel designed to minimize volume expansion, foaming, and aeration during blending processes. These tanks are commonly used in industries where controlled mixing is essential for maintaining product consistency and quality.

A Low Expansion Atmospheric Tank is a storage vessel designed to hold and blend liquids while minimizing volume expansion, foaming, and aeration. These tanks operate at atmospheric pressure (0 psig) and are commonly used in industries such as food and beverage, pharmaceuticals, chemicals, and petroleum.

Low-Expansion Nozzles

Low-expansion nozzles develop expansion ratios up to 20:1. Low-expansion nozzles produce wet or Fluid foam that is most effectively used for exposure protection, direct attack, & overhaul.

High Expansion Foam Flooding System

The high-expansion foam is particularly suitable for extinguishing _res of solid fuels as well as paper or wood fire. A depth fire can be suppressed over a long period and the foam wet action penetrates deeper than the normal action of the water. The foam in a fire, creates a protective barrier for exposed materials and the structure is not directly involved in the fire.

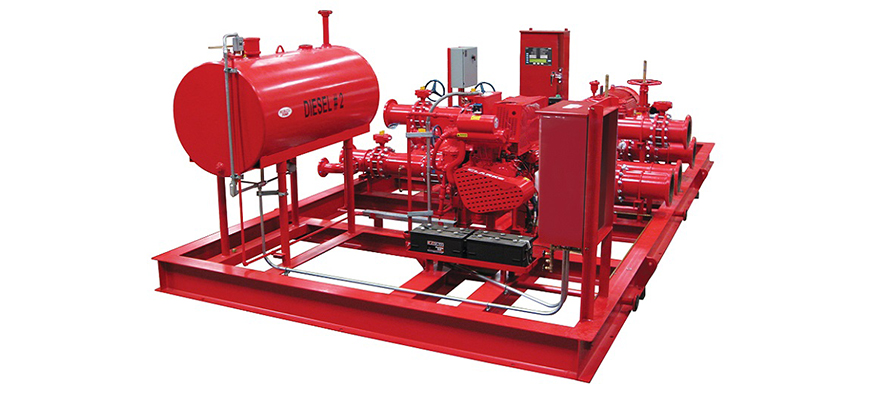

Foam Skid System

A Foam Skid System is a self-contained firefighting unit designed to generate and deliver firefighting foam for suppressing flammable liquid fires, such as those involving petroleum, chemicals, and other hazardous materials. These systems are commonly used in industrial facilities, refineries, airports, marine applications, and hazardous material storage areas.

Foam Poring System

Foam Chamber is used in one of the most common application to protect vertical fixed roof (cone) liquid storage tanks, with or without internal floating roof with the low expansion foam system. The application of foam is on the basis that the risk comprises the total surface area of the fuel. The foam system design guidelines generally used are in accordance with NFPA- 11, standard. Foam chambers are defined by NFPA-11 as Type II discharge outlets for delivering the foam to the surface of a flammable liquid. The Foam Chambers are widely used with the Inline Foam Inductor, Balance Pressure Foam Proportioning system, Bladder Tank Proportioner or Foam Tender.

MICRO FIRE © 2024 / ALL RIGHTS RESERVED

Developed by VK TECHSOL